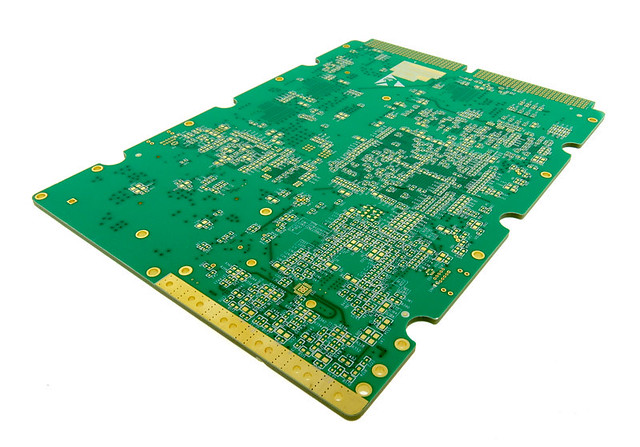

High Frequency PCB: The Revolution in Electronic Manufacturing

Introduction:

In the fast-paced world of electronics, High Frequency PCB (Printed Circuit Boa Microwave PCB rd) has emerged as a game-changer. Its ability to handle high-frequency signals and deliver exceptional performance has made it an indispensable component for various applications. This article explores the manufacturing process, characteristics, advantages, usage methods, tips for selecting this product, and concludes with its significance.

Manufacturing Process:

High Frequency PCB is produced using advanced techniques that involve specific materials and meticulous fabrication processes. The base material selection plays a crucial role in achieving desired electrical properties. Materials such as PTFE (Polytetrafluoroethylene) are pop High Frequency PCB ularly used due to their low dielectric loss and excellent insulation characteristics. These substrates undergo precise drilling, lamination, copper plating, etching, solder mask application, and surface finishing.

Characteristics:

1. Low Signal Loss: High Frequency PCBs exhibit m

inimal signal loss during transmission due to their low dielectric constant and dissipation factor.

2. Impedance Control: These boards ensure accurate impedance control by carefully designing trace widths, thicknesses,an High-frequency PCB manufacturer d layer stackups based on the target frequency.

3.Improved Heat Dissipation: With efficient thermal management mechanisms like metal core substrates or embedded heat sinks,such PCBs excel in dissipating heat generated by high-power components.

4.Tightly Compact Designs:The HDI-PCB(High Density Interconnect-Printed Circuit Board) technology enables designers to achieve highly compact layouts with finer traces,a higher number of interconnections amidthe ever-decreasing size requirements.

5.Signal Integrity Maintenance:The specialized design reduces noise interference,maintaining reliable signal integrity for critical applications.

Advantages:

1.Enhanced Pe HDI-PCB (High Density Interconnect-Printed Circuit Board) rformance: High Frequency PCBs provide superior performance compared to conventional circuit boards when dealing with high-frequency signals related todigital networks,wireless communication systems,radar systems,and microwaveapplications。

2. Higher Reliability: These boards undergo rigorous testing to ensure reliability and durability in demanding environments, such as aerospace, telecommunications,automotive,and medical fields.

3.Cost Efficiency LED PCB manufacturer : While the initial production cost of High Frequency PCBs may be higher due to advanced materials and complex manufacturing processes,the long-term benefits outweigh them by reducing signal losses,maintenance costs,frequency interferences,and system failures.

Usage Methods:

1. Microwave PCB for Radar Systems: In radar systems, microwave fr High Frequency PCB equencies are utilized for detecting objects accurately.High Frequency PCBs with their low-loss property help optimize the overall performance of radar systems by ensuring efficient transmission and reception signals.

2.Signal Integrity PCB for Telecommunication Networks: Maintaining signal integrity is crucial in high-speed telecommunication networks where data loss or distortion can hamper the quality.To overcome these challenges, Signal Integrity PCBs are preferred to minimize crosstalk, reduce electromagnetic interference(EMI),and ma High-frequency PCB manufacturer intain optimum signal fidelity.

How to Select the Right Product:

Choosing the right High Frequency PCB manufacturer is essential for obtaining a reliable product that meets specific requirements. Consideration should be given to:

1.Experience and Expertise: Look for manufacturers who have years of experience in High Frequency PCB producing high-quality High-FrequencyPCBs.

2.Material Selection: Ensure that the manufacturer uses top-grade base materials like PTFE with consistent thicknesses and properties.

3.Quality Assurance Measures:The chosen manufacturer must adhere to strict quality control standards throughout the manufacturing process while complying with industry norms such as IPC-A-600(F-Class2).

Conclusion:

High-frequency printed circuit boards have revolutionized electronic manufacturing due to their exceptional characteristics,such as low signal lo

ss,optimum impedance control,tighter designs,and superior heat dissipation.Capable of handling increasing demands for wireless communication,radar systems,internet connectivity via 5G,and IoT devices,these boards provide enhanced performance,reliability,cost efficiency.The key lies in selecting experienced manufacturers adheringto stringent quality standards.

As technology evolves, the importance of High Frequency PCBs will continue to grow, making them a critical component in numerous industries. Embracing Signal Integrity PCB this advanced technology is essential for staying ahead in today’s ever-advancing electronic world.